What Is The Most Scratch Resistant Flooring To Buy?

Selecting the right flooring for a home or business involves careful consideration of various factors, including aesthetics, cost, maintenance, and durability. Among durability concerns, scratch resistance is often a top priority, especially in high-traffic areas or households with pets and children. Understanding the different types of flooring materials and their inherent resistance to scratches is crucial for making an informed purchasing decision. This article will explore several flooring options, analyzing their composition, manufacturing processes, and performance in resisting scratches, indentations, and other forms of surface damage.

The term "scratch-resistant" can be somewhat misleading, as no flooring material is entirely immune to scratches under all circumstances. Instead, the degree of scratch resistance varies depending on the material's hardness, surface treatment, and the type of abrasive force applied. Therefore, it is more accurate to consider floors as being more or less scratch-resistant relative to one another. Understanding the distinction and the relative scratch resistance of different flooring is vital for matching the right flooring to your needs.

Understanding the Mohs Hardness Scale

The Mohs Hardness Scale, while primarily used for minerals, provides a useful benchmark for understanding the relative hardness and scratch resistance of various flooring materials. The scale ranges from 1 (talc) to 10 (diamond), with higher numbers indicating greater resistance to scratching. While flooring is not rated directly on the Mohs scale, the composition of the materials used can be correlated to the scale, providing a general understanding of their scratch resistance.

For example, materials containing minerals with a high Mohs hardness, such as aluminum oxide found in many durable finishes, contribute significantly to increased scratch resistance. Conversely, softer materials without protective finishes are inherently more susceptible to surface abrasion. The Mohs Hardness Scale helps in discerning the inherent scratch resistance that is available in different materials and flooring options.

It's also important to note that the Mohs Hardness Scale primarily assesses resistance to scratching by harder materials. It doesn't necessarily correlate directly with resistance to indentation or impact damage, which are separate considerations when selecting flooring. A flooring material might be highly scratch-resistant but still vulnerable to dents from heavy objects or sharp impacts.

Evaluating Flooring Options for Scratch Resistance

Several flooring options offer varying degrees of scratch resistance. These include hardwood, laminate, luxury vinyl, tile, and concrete. Each possesses unique characteristics that influence its performance under abrasive conditions.

Hardwood Flooring: Solid hardwood is a popular choice for its natural beauty and timeless appeal. However, its scratch resistance depends on the type of wood species and the finish applied. Harder wood species, such as hickory, maple, and oak, are more resistant to scratching than softer species like pine or cherry. Additionally, the finish plays a crucial role. Polyurethane finishes, especially those with multiple coats and a high solids content, provide a durable protective layer. However, even the best polyurethane finishes can be scratched over time, particularly by pet claws or abrasive dirt. Engineered hardwood flooring, which consists of a thin layer of hardwood veneer over a core of plywood or MDF, offers similar scratch resistance to solid hardwood, depending on the thickness of the veneer and the quality of the finish.

Laminate Flooring: Laminate flooring is a synthetic product consisting of a photographic image layer sandwiched between a wear layer and a core board. The wear layer, typically made of aluminum oxide, is the primary determinant of scratch resistance. Higher-quality laminates with thicker wear layers offer superior protection against scratches and scuffs. The Abrasion Class (AC) rating, ranging from AC1 to AC5, indicates the durability of the wear layer. AC3 is generally suitable for residential use, while AC4 and AC5 are recommended for higher-traffic areas and commercial applications. Laminate flooring offers a cost-effective alternative to hardwood, providing good scratch resistance at a lower price point.

Luxury Vinyl Flooring (LVF): Luxury vinyl flooring comes in planks (LVP) or tiles (LVT) and is known for its durability, water resistance, and realistic appearance. Similar to laminate, the wear layer is the key factor in scratch resistance. Thicker wear layers, measured in mils (thousandths of an inch), offer better protection. A wear layer of 20 mils or higher is generally recommended for high-traffic areas or homes with pets. LVF is more resilient than hardwood or laminate, meaning it is less prone to denting and can withstand more impact. The composition of the vinyl itself also contributes to its scratch resistance; some LVF products incorporate mineral fillers or enhanced surface treatments to further improve durability.

Tile Flooring: Tile flooring, particularly porcelain tile, is among the most scratch-resistant flooring options available. Porcelain tile is fired at high temperatures, resulting in a dense, hard material that is highly resistant to scratches, stains, and moisture. The Porcelain Enamel Institute (PEI) rating, ranging from 1 to 5, indicates the tile's abrasion resistance. A PEI rating of 3 or higher is suitable for residential flooring, while a rating of 4 or 5 is recommended for high-traffic areas and commercial applications. While tile itself is highly scratch-resistant, the grout lines between tiles are more susceptible to staining and damage. Regular cleaning and sealing of the grout can help maintain its appearance and prevent degradation.

Concrete Flooring: Concrete flooring, when properly sealed and finished, offers excellent scratch resistance and durability. Polished concrete, in particular, is a popular choice for its modern aesthetic and low maintenance requirements. The polishing process densifies the concrete surface, making it more resistant to abrasion and staining. Additionally, sealants and coatings, such as epoxy or polyurethane, provide a protective layer that further enhances scratch resistance. Concrete is an extremely durable material, but it can be susceptible to cracking or chipping, especially if not properly installed or maintained. However, for overall scratch resistance, it is one of the better options.

Key Factors Influencing Scratch Resistance

While the inherent properties of the flooring material play a significant role in scratch resistance, several other factors can influence its performance. These factors include:

Surface Finish: The type and quality of the surface finish are critical in protecting the underlying material from scratches. Polyurethane finishes on hardwood, aluminum oxide wear layers on laminate and luxury vinyl, and sealants on concrete all contribute to increased scratch resistance. Consider using finishes with UV inhibitors to protect the floor from fading from the sun.

Foot Traffic: The amount and type of foot traffic a floor receives directly impact its likelihood of being scratched. High-traffic areas, such as hallways, entryways, and kitchens, are more susceptible to scratching than low-traffic areas. The type of footwear worn also plays a role; high heels, work boots, and shoes with rough soles can cause more damage than soft-soled shoes or bare feet.

Pet Activity: Pets, especially dogs with untrimmed nails, can cause significant scratching to flooring. Regular nail trimming and the use of area rugs can help mitigate this risk. Some flooring options, such as luxury vinyl and tile, are more pet-friendly than others due to their inherent scratch and stain resistance.

Maintenance Practices: Proper maintenance is essential for preserving the scratch resistance and overall appearance of flooring. Regular sweeping or vacuuming removes abrasive dirt and debris that can cause scratches. Using appropriate cleaning products and avoiding harsh chemicals can prevent damage to the surface finish. Promptly cleaning up spills and stains can prevent permanent discoloration or damage.

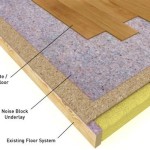

Underlayment: The type of underlayment used beneath the flooring can also influence its scratch resistance. A supportive and stable underlayment can help prevent flexing or movement that can contribute to scratching. Underlayment also helps in general floor performance such as shock absorption, impact absorption, and sound dampening.

The Role of Surface Treatments and Coatings

Beyond the inherent properties of the flooring material, specialized surface treatments and coatings can significantly enhance scratch resistance. These treatments typically involve applying a protective layer that is harder and more durable than the underlying material. Examples include:

- Aluminum Oxide: As mentioned earlier, aluminum oxide is a common component of wear layers in laminate and luxury vinyl flooring. It is an extremely hard and abrasion-resistant material that provides excellent protection against scratches.

- Ceramic Bead Technology: Some manufacturers incorporate ceramic beads into their surface finishes to increase scratch resistance. These beads are microscopic in size and are evenly dispersed throughout the finish, creating a tough and durable surface.

- UV Cured Finishes: UV cured finishes, which are hardened using ultraviolet light, offer exceptional durability and scratch resistance. These finishes are commonly used on hardwood and luxury vinyl flooring.

- Scratch-Resistant Coatings: Various scratch-resistant coatings are available for application to existing flooring. These coatings typically consist of polyurethane or epoxy resins and are designed to provide a protective barrier against scratches and scuffs.

These treatments and coatings are designed to provide an extra layer of protection against daily wear and tear. While no coating is completely scratch-proof, selecting flooring with these enhanced treatments can significantly improve its long-term appearance and durability.

Selecting the most scratch-resistant flooring involves a careful evaluation of various factors, including the type of material, the surface finish, the level of foot traffic, and the presence of pets. While no flooring is entirely immune to scratches, understanding the different options and their relative strengths can help buyers make an informed decision that meets their specific needs and lifestyle. The more information that you have on the material's construction, the more informed your opinion will be.

Best Waterproof My Dad S Flooring America

Best Waterproof My Dad S Flooring America

Best Waterproof My Dad S Flooring America

8 Most Durable Options For Flooring Lx Hausys

4 Of The Most Durable Flooring Options For Your Home Twenty Oak

Waterproof Scratchless Flooring Collection Coretec

Discover The Best Scratch Resistant Wood Flooring Superior S Graham And Son

Hardwood Flooring That Will Not Scratch Garrison Collection

Are There Any Scratch Resistant Hardwood Flooring Options Woodfloor Masters Inc

Top 6 Exclusive Water Resistant And Waterproof Floors

See Also