Can You Paint Subfloor With Kilz? A Comprehensive Guide

The question of whether to paint a subfloor, and specifically whether Kilz primer is a suitable option, is one that arises frequently during flooring projects. Subfloors, the foundational layer beneath the finished flooring, are typically constructed from plywood or OSB (Oriented Strand Board). They are susceptible to moisture damage, mold growth, and odors, making surface treatment a consideration for many homeowners and contractors. This article will explore the advantages and disadvantages of using Kilz primer on subfloors, examine alternative products, and outline best practices for subfloor treatment.

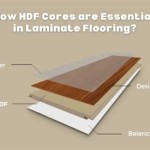

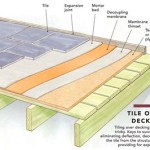

Before delving into the specifics of Kilz, it's crucial to understand the purpose of a subfloor. The primary function is to provide a stable, level surface for the finished flooring material. This stability prevents flexing, squeaking, and uneven wear and tear on the overlying floor. However, subfloors are often exposed to moisture during construction and can absorb spills or humidity over time. This absorbed moisture can lead to a host of problems, including warping, rotting, mold, and unpleasant odors. Treating the subfloor with a protective coating aims to mitigate these issues.

Kilz is a well-known brand of primers and paints, widely recognized for its stain-blocking and adhesion properties. Different Kilz products exist, each formulated for specific applications. Understanding the different types of Kilz is essential before considering its use on a subfloor. Common formulations include oil-based, latex-based, and water-based primers as well as specialized mold and mildew-resistant primers. The selection of the appropriate Kilz product will depend on the specific concerns regarding the subfloor, such as existing stains, potential for moisture exposure, and the type of flooring to be installed.

Understanding Kilz Primer Formulations and Their Suitability for Subfloors

Kilz offers a range of primers, each with distinct characteristics that may make it more or less suitable for use on a subfloor. Oil-based Kilz primers are known for their excellent stain-blocking capabilities and adhesion to various surfaces. They are particularly effective at sealing in odors and preventing bleed-through from stains caused by water damage or pet urine. However, oil-based primers have a strong odor, require mineral spirits for cleanup, and can be more prone to cracking over time compared to latex-based alternatives. Their extended drying time can also delay flooring installation. Therefore, while oil-based Kilz offers robust stain blocking, the drawbacks may outweigh the benefits in certain situations.

Latex-based Kilz primers, on the other hand, are water-based, low-VOC (Volatile Organic Compounds), and easier to clean up. They offer good adhesion and are less likely to crack than oil-based primers. While latex-based Kilz primers provide good stain blocking, they may not be as effective as oil-based primers on heavily stained surfaces. Furthermore, some latex-based primers are not specifically formulated for mold and mildew resistance, which can be a significant concern in damp environments. Carefully reviewing the product specifications is crucial to ensure the selected primer meets the requirements of the subfloor.

Water-based Kilz primers represent a newer generation of primers that often combine the low-VOC and easy cleanup benefits of latex-based primers with enhanced stain-blocking and adhesion properties. Some water-based Kilz primers are specifically formulated to be mold and mildew resistant, making them a more appealing option for subfloors that are prone to moisture exposure. These primers often offer excellent coverage and can be tinted to improve the hiding power of the topcoat. Understanding the specific formulation and intended use of each Kilz product is paramount to making an informed decision.

Advantages of Using Kilz on Subfloors

The primary advantage of using Kilz primer on a subfloor is its ability to seal the surface and prevent stains and odors from penetrating the flooring material. This is particularly important if the subfloor has been exposed to water damage, pet urine, or other contaminants. By creating a barrier, Kilz primer can prevent these issues from affecting the appearance and hygiene of the finished floor. Additionally, Kilz primer can improve the adhesion of the flooring adhesive, ensuring a more secure and long-lasting bond. This is particularly beneficial for flooring types such as tile and vinyl, which rely on a strong adhesive bond to prevent movement and cracking.

Another advantage of using Kilz primer is its ability to create a more uniform surface for the flooring material. Subfloors, particularly those made from OSB, can have a rough or uneven texture. Applying Kilz primer can fill in minor imperfections and create a smoother surface, resulting in a more professional and aesthetically pleasing finished floor. This is particularly important for thin flooring materials such as vinyl sheet or laminate, which can telegraph imperfections in the subfloor.

Furthermore, some Kilz primers are specifically formulated to be mold and mildew resistant. This is a significant benefit for subfloors that are exposed to moisture or humidity, as it can help to prevent the growth of mold and mildew, which can cause health problems and structural damage. These mold and mildew-resistant primers typically contain biocides that inhibit the growth of these organisms. However, it's important to note that these primers are not a substitute for addressing the underlying cause of the moisture problem.

Considerations and Potential Drawbacks of Using Kilz on Subfloors

While Kilz primer offers several benefits for subfloor treatment, there are also potential drawbacks to consider. One of the main concerns is the potential for trapping moisture within the subfloor. If the subfloor is already damp or prone to moisture absorption, applying a primer can create a barrier that prevents the moisture from escaping. This can lead to trapped moisture, which can promote mold growth and accelerate wood rot. Therefore, it's essential to ensure that the subfloor is thoroughly dry before applying any type of primer.

Another consideration is the compatibility of the primer with the flooring adhesive. Some flooring adhesives may not adhere properly to certain types of primers, leading to flooring failure. It's crucial to check the flooring adhesive manufacturer's recommendations to ensure compatibility with the chosen primer. In some cases, the manufacturer may recommend a specific type of primer or require that the primer be sanded before applying the adhesive.

Furthermore, the application of Kilz primer can add to the overall cost and time of the flooring project. The cost of the primer itself, as well as the time required for application and drying, should be factored into the budget and schedule. In some cases, alternative subfloor treatments, such as vapor barriers or self-leveling compounds, may offer a more cost-effective or time-efficient solution. The decision of whether to use Kilz primer should be based on a careful assessment of the specific needs and conditions of the subfloor.

Proper surface preparation is crucial for achieving optimal results when using Kilz primer on a subfloor. The subfloor should be clean, dry, and free from debris, dirt, and loose particles. Any existing stains or mold growth should be thoroughly cleaned and treated before applying the primer. Cracks and imperfections should be filled with a suitable patching compound. Sanding the subfloor can help to create a smoother surface and improve adhesion. Following the manufacturer's instructions for surface preparation is essential for ensuring a successful application.

When applying Kilz primer, it's important to use the appropriate tools and techniques. A high-quality paint roller or brush should be used to apply the primer evenly and uniformly. Multiple thin coats are generally preferable to a single thick coat, as this can help to prevent runs and drips. The primer should be allowed to dry completely before applying the flooring adhesive or installing the flooring material. Proper ventilation is also important during application and drying, as some Kilz primers can emit strong odors. Following the manufacturer's safety precautions is essential to protect oneself from potential hazards.

In conclusion, while Kilz primer can be a beneficial product for treating subfloors, it's important to consider the potential drawbacks and ensure that it's the appropriate solution for the specific needs and conditions of the subfloor. Proper surface preparation, application techniques, and compatibility with the flooring adhesive are crucial for achieving optimal results. Alternative subfloor treatments should also be considered to determine the most cost-effective and time-efficient solution. A thorough assessment of the situation will ensure the longevity and performance of the finished flooring.

Kilz Restoration Interior Primer

A Bathroom Remodel Project With Kilz Primers Blog

How To Primer Sub Floor With Kilz Original Stain Odor Blocker

Painted Floors And Struggles With Contentment Sand Sisal

A Bathroom Remodel Project With Kilz Primers Blog

Painting Stenciling A Floor The Painted Hive

8 Pack Of 1 Gal Masterchem L200201 Restoration Water Based Interior Primer Multi Surface Paints Primers Specialty Coatings

Diy Painted Osb Floors Mmmm Teal Dans Le Lakehouse

Diy Painted Osb Floors Mmmm Teal Dans Le Lakehouse

Have A Question About Kilz Restoration 5 Gal White Interior Primer Sealer And Stain Blocker Pg 4 The Home

See Also