Choosing the Best Quality Engineered Hardwood Flooring for Your Home

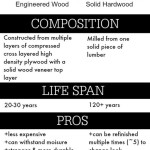

Engineered hardwood flooring has become a popular choice for homeowners looking for the beauty and durability of hardwood without the cost and maintenance of solid hardwood. Engineered hardwood is made with a top layer of real hardwood veneer bonded to a core of plywood or another composite material. This construction makes engineered hardwood more stable and less likely to warp or cup than solid hardwood. It is also more resistant to moisture and scratches, making it a good choice for high-traffic areas and homes with pets and children.

When choosing engineered hardwood flooring, there are several factors to consider to ensure you get the best quality product for your home. Here are some of the most important aspects to keep in mind:

1. Species of Hardwood: The species of hardwood used for the top layer of engineered hardwood will affect its durability, color, and grain pattern. Some popular hardwood species used for engineered flooring include oak, maple, walnut, and cherry. Oak is a durable, versatile wood with a wide range of colors and grain patterns. Maple is another durable wood with a light, creamy color. Walnut is a rich, dark wood with a beautiful grain pattern. Cherry is a reddish-brown wood with a fine grain pattern.

2. Thickness of Wear Layer: The wear layer is the top layer of hardwood on engineered flooring. The thickness of the wear layer will determine how well the flooring will resist wear and tear. A thicker wear layer will last longer and be more resistant to scratches and dents. Wear layers can range in thickness from 0.5mm to 6mm, with 2mm being the most common for residential use.

3. Construction: The construction of engineered hardwood flooring refers to the materials used for the core and backing of the flooring. The core is typically made of plywood, high-density fiberboard (HDF), or a combination of both. The backing is a thin layer of material that is attached to the bottom of the core to provide stability and moisture resistance. The type of core and backing used will affect the durability, stability, and moisture resistance of the flooring.

4. Finish: The finish of engineered hardwood flooring is responsible for protecting the wood from wear and tear and giving it its desired appearance. There are several different types of finishes available, including polyurethane, aluminum oxide, and UV-cured finishes. Polyurethane finishes are the most common and offer good protection against wear and tear. Aluminum oxide finishes are more durable and scratch-resistant than polyurethane finishes. UV-cured finishes are the most durable and scratch-resistant but also the most expensive.

5. Warranty: The warranty on engineered hardwood flooring will vary depending on the manufacturer. A good warranty will cover the flooring against defects in materials and workmanship for a specified period of time. A longer warranty period indicates that the manufacturer is confident in the quality of their product.

By considering these factors, you can choose the best quality engineered hardwood flooring for your home that will meet your needs and budget. Engineered hardwood flooring is a beautiful, durable, and affordable option for homeowners who want the look and feel of hardwood without the drawbacks of solid hardwood.

The 15 Best Engineered Wood Flooring Brands Reviews 2024 Floorings

Types Of Hardwood Flooring Forbes Home

Tips For Choosing The Best Hardwood Flooring Option Your Home 360 Floors Design Llc

What You Need To Know About Engineered Hardwood Flooring Renaissance Floors

How To Choose The Right Wooden Flooring Cost Maintenance Lifespan

Choosing The Best Color Of Hardwood Floor For Your Home

Selecting The Right Flooring For Your New Home

Engineered Wood Vs Solid Hardwood

10 Beautiful Dark Hardwood Floors To Transform Your Home Next Day

Engineered Wood Flooring Vs Diffe Types Hardwoodfloor

See Also