Engineered Wood vs. Solid Flooring: A Cost Comparison

When undertaking a flooring project, one of the most crucial decisions revolves around the type of material to use. Engineered wood and solid hardwood flooring are two popular choices, each possessing distinct characteristics that influence their performance, aesthetics, and, most importantly, overall cost. A comprehensive understanding of the cost factors associated with both options is essential for making informed decisions that align with budgetary constraints and long-term flooring needs.

This article provides a detailed comparison of the cost implications involved in selecting engineered wood versus solid hardwood flooring. The analysis will encompass material costs, installation expenses, maintenance requirements, and long-term value considerations to provide a holistic perspective on the financial aspects of each flooring type.

Understanding the Composition and Construction Differences

Before delving into the cost analysis, it is crucial to establish a clear understanding of the fundamental differences in composition and construction between engineered wood and solid hardwood flooring. This understanding forms the basis for the variations observed in pricing and other cost-related aspects.

Solid hardwood flooring consists of planks milled from a single piece of wood. The species of wood used (oak, maple, walnut, etc.) directly influences its hardness, grain pattern, and overall aesthetic appeal. Solid hardwood is known for its natural beauty, durability, and potential for refinishing multiple times throughout its lifespan.

Engineered wood flooring, on the other hand, is composed of multiple layers. The top layer, known as the veneer, is a thin slice of real hardwood. This veneer provides the desired visual appearance. Beneath the veneer lies a core, often constructed from plywood, high-density fiberboard (HDF), or other composite materials. This multi-layered construction offers enhanced dimensional stability compared to solid hardwood, making it less susceptible to expansion and contraction due to changes in humidity and temperature.

The difference in construction methodology directly impacts the raw material costs. Solid hardwood requires a substantial amount of a specific wood species, whereas engineered wood uses a smaller quantity of the desired wood for the veneer, with the core being composed of potentially less expensive materials.

Direct Material Costs: Initial Purchase Price

The initial purchase price is often the primary consideration when evaluating flooring options. Generally, solid hardwood flooring tends to have a higher upfront cost compared to engineered wood flooring, although this is not always the case and depends on a multitude of factors.

The cost of solid hardwood is significantly affected by the species of wood. Common hardwoods like oak and maple are typically more affordable than exotic or rare species such as Brazilian cherry or ebony. Wider planks and longer lengths of solid hardwood also command a higher price due to increased material usage and manufacturing complexity.

Engineered wood flooring also exhibits price variations based on the wood species used for the veneer. However, the core material plays a significant role in determining the overall cost. Engineered flooring with an HDF core is generally less expensive than those with a plywood core, which offers superior moisture resistance and structural integrity. The thickness of the veneer also contributes to the price. Thicker veneers allow for more refinishing opportunities, increasing the value and, consequently, the cost.

Beyond wood species and core composition, the finish applied to both solid hardwood and engineered wood can influence the price. Pre-finished flooring, offering convenience and consistent finish quality, may be more expensive than unfinished options that require on-site finishing. Specialized finishes, such as hand-scraped or distressed textures, often add a premium to the cost.

When comparing material costs, it is imperative to obtain quotes from multiple suppliers and factor in the total square footage required for the project. Volume discounts and promotional offers can potentially lower the overall material expenses.

Installation Costs: Labor and Underlying Preparation

While the material cost is a significant factor, the installation expenses associated with both types of flooring can significantly impact the total project budget. Installation costs encompass labor fees, necessary underlayment, and any subfloor preparation required.

Solid hardwood flooring typically requires professional installation due to its more complex installation methods. It is often nailed or stapled to a wooden subfloor. The preparation of the subfloor is critical to ensure a level and stable surface. Irregularities in the subfloor can lead to uneven flooring, squeaks, and premature wear. Subfloor preparation might involve leveling compounds, plywood sheeting, or structural repairs, adding to the overall installation cost.

Engineered wood flooring offers more versatility in installation methods. It can be glued down, nailed, stapled, or installed as a floating floor. Floating floor installations, where the planks interlock without being directly fastened to the subfloor, are often less expensive to install. This method can also be suitable for installation over existing flooring, saving on demolition and subfloor preparation costs.

The choice of installation method for engineered wood depends on the specific product specifications, the condition of the subfloor, and the desired level of stability. Gluing down engineered wood provides a more solid feel but is generally more labor-intensive than floating installations.

Labor costs vary depending on the region, the complexity of the installation, and the experience of the installer. Obtaining multiple quotes from qualified and licensed flooring contractors is crucial to ensure competitive pricing and quality workmanship. Clearly define the scope of work, including subfloor preparation, trim installation, and disposal of old flooring, to avoid unexpected costs.

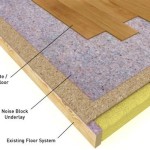

Underlayment is a critical component of the installation process for both solid hardwood and engineered wood flooring, particularly for floating installations. Underlayment provides cushioning, sound insulation, and moisture protection. The type of underlayment required depends on the specific flooring product and the subfloor conditions. Thicker, higher-quality underlayments offer better performance but come at a higher cost.

Long-Term Costs: Maintenance, Refinishing, and Lifespan

Beyond the initial purchase and installation costs, the long-term expenses associated with maintaining, repairing, and potentially replacing the flooring must be considered. Solid hardwood and engineered wood flooring have different maintenance requirements and varying lifespans, which influence their overall cost-effectiveness.

Solid hardwood flooring is renowned for its longevity. With proper care and maintenance, it can last for decades, even centuries. Regular cleaning, periodic screening and recoating, and occasional refinishing can restore its original beauty and extend its lifespan. Refinishing involves sanding down the existing finish and applying a new coat of stain and sealant. Solid hardwood can typically be sanded and refinished multiple times, making it a long-lasting and potentially cost-effective option in the long run.

Engineered wood flooring's lifespan is generally shorter than that of solid hardwood, depending on the thickness of the veneer. Thicker veneers can withstand more sanding and refinishing, extending the flooring's lifespan. However, engineered wood with thin veneers may only be refinished once or twice, or not at all, before the veneer is compromised. Replacing engineered wood flooring is typically more expensive than refinishing solid hardwood.

Maintenance costs for both types of flooring are relatively similar. Regular sweeping or vacuuming to remove dirt and debris is essential. Occasional damp mopping with a cleaner specifically designed for wood floors helps maintain the finish and prevent damage. Avoiding excessive moisture, using furniture pads, and promptly addressing spills can prolong the life of both solid hardwood and engineered wood flooring.

The need for repairs can arise from scratches, dents, or water damage. Spot repairs can often be performed on both types of flooring. However, extensive damage may require replacing individual planks or sections of the flooring. The cost of repairs depends on the extent of the damage and the availability of matching replacement planks.

When evaluating long-term costs, it is prudent to consider the potential resale value of the property. Solid hardwood flooring is often perceived as a higher-end feature that can increase a home's value. Engineered wood flooring can also add value, particularly if it features a high-quality veneer and is well-maintained.

In summary, while solid hardwood may have a higher initial cost, its longevity and potential for multiple refinishing cycles can make it a cost-effective option over the long term. Engineered wood flooring offers a more affordable upfront cost and easier installation but may have a shorter lifespan and fewer refinishing opportunities.

Other Considerations that Influence Costs

Beyond the factors already discussed, several other considerations can influence the overall cost of engineered wood and solid hardwood flooring projects. These include:

Subfloor Condition: The condition of the existing subfloor can significantly impact preparation costs. Uneven, damaged, or contaminated subfloors require extensive repairs or replacement, adding to the overall project expense. Properly assessing the subfloor is crucial before selecting a flooring material and obtaining installation quotes.

Moisture Levels: Excessive moisture in the subfloor or surrounding environment can damage both solid hardwood and engineered wood flooring. Moisture testing is essential to identify and address any moisture issues before installation. Mitigation measures, such as moisture barriers or dehumidifiers, may be necessary, adding to the overall cost.

Geographic Location: Flooring costs can vary significantly depending on the geographic location. Labor rates, material availability, and local market demand influence pricing. Obtaining quotes from local suppliers and contractors is crucial to ensure accurate cost estimates.

Disposal Costs: The cost of removing and disposing of existing flooring can add to the overall project expense. Disposal fees vary depending on the type of flooring and local regulations. Some contractors include disposal costs in their installation quotes, while others charge separately.

Permits and Inspections: Depending on the scope of the project and local building codes, permits and inspections may be required. Permit fees and inspection costs should be factored into the overall budget.

By carefully considering these additional factors and conducting thorough research, homeowners can make informed decisions about which flooring option best suits their needs and budget.

Solid Vs Engineered Hardwood Which Is Better

Hardwood Vs Engineered Wood Flooring Which Is Better Bessemeter

Engineered Wood Vs Hardwood What S The Difference

Solid Vs Engineered Hardwood Which Is Better

Solid Vs Engineered Quality Hardwoods Superior Design Palo Duro

How To Choose Between Engineered Solid Wood Flooring Adige Design

Engineered Vs Solid Wood Flooring Main Differences Esb

Engineered Wood Flooring Vs Solid Forté

Solid Vs Engineered Hardwood Floors What S The Difference

Laminate Flooring Vs Engineered Hardwood Pros And Cons

See Also