Does Vinyl Plank Flooring Move? Understanding Movement and Stability

Vinyl plank flooring, particularly luxury vinyl plank (LVP) and luxury vinyl tile (LVT), has gained immense popularity as a durable, aesthetically versatile, and often cost-effective flooring option. Its resemblance to hardwood and tile, coupled with its water resistance and ease of maintenance, makes it an attractive choice for various residential and commercial spaces. However, a common concern among potential buyers revolves around the potential for movement in vinyl plank flooring, specifically whether it expands, contracts, or shifts after installation.

Understanding the composition and installation methods of vinyl plank flooring is crucial to addressing this concern. Vinyl planks are primarily made from PVC (polyvinyl chloride) and other plasticizers. These materials are susceptible to dimensional changes based on temperature fluctuations. Moreover, the method of installation – whether it's glue-down, click-lock, or loose-lay – significantly impacts the flooring's stability and susceptibility to movement. The degree of movement can vary depending on the quality of the vinyl, the specific installation technique, and the environmental conditions within the space.

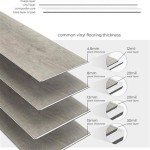

Different types of vinyl plank flooring exhibit varying degrees of dimensional stability. Standard vinyl plank, often thinner and less dense, tends to be more susceptible to expansion and contraction than luxury vinyl plank, which is thicker, often reinforced with a core layer, and designed for greater stability. The following sections will explore the factors that contribute to vinyl plank movement and how to mitigate potential issues.

Temperature and Humidity's Effect on Vinyl Plank Dimensional Stability

Temperature variations are the foremost cause of expansion and contraction in vinyl plank flooring. As the ambient temperature rises, the vinyl material expands. Conversely, as temperatures drop, it contracts. This is a fundamental property of PVC and other plastics. The extent of this expansion and contraction depends on the specific formulation of the vinyl and the magnitude of the temperature change.

Humidity also plays a role, although a less significant one compared to temperature. While vinyl is generally water-resistant, excessive humidity can lead to minor dimensional changes, particularly in lower-quality vinyl planks. In areas with high humidity, it's essential to ensure proper ventilation and climate control to minimize the potential for these changes.

The manufacturer's specifications typically provide information on the acceptable temperature and humidity ranges for optimal performance. Adhering to these guidelines is essential to prevent excessive movement that could lead to gapping, buckling, or other issues. Before installation, acclimating the vinyl planks to the room's conditions for a specified period (usually 48-72 hours) is crucial. This allows the material to adjust to the ambient temperature and humidity levels, minimizing post-installation movement.

Furthermore, radiant heating systems beneath vinyl plank flooring can exacerbate expansion and contraction if not properly managed. It's essential to consult with the vinyl plank manufacturer and the radiant heating system provider to ensure compatibility and adherence to recommended temperature limits. Gradual and controlled temperature increases and decreases are recommended to prevent sudden shocks to the flooring material.

Installation Methods and their Impact on Stability

The method of installation significantly impacts the stability and movement of vinyl plank flooring. There are three primary installation methods: glue-down, click-lock (also known as floating), and loose-lay. Each has its advantages and disadvantages regarding its resistance to movement.

Glue-down Installation: This method involves applying a layer of adhesive to the subfloor and pressing the vinyl planks firmly into the adhesive. Glue-down provides the most stable installation, as the planks are rigidly bonded to the subfloor. This minimizes the potential for expansion, contraction, and shifting. However, glue-down installation requires a perfectly smooth and level subfloor, as any imperfections will telegraph through the vinyl. It is also more difficult to remove or replace individual planks compared to other methods.

Click-Lock (Floating) Installation: Click-lock vinyl planks have interlocking edges that snap together, creating a "floating" floor that is not directly attached to the subfloor. This method is easier to install than glue-down, as it requires no adhesive. However, floating floors are more susceptible to expansion and contraction. A gap (usually around ¼ inch) is left around the perimeter of the room, covered by baseboards or molding, to allow for expansion and contraction. Without this expansion gap, the floor can buckle or warp as the planks push against each other. The quality of the click-lock mechanism also affects stability; better-quality systems provide a tighter, more secure connection, reducing the likelihood of movement.

Loose-Lay Installation: Loose-lay vinyl planks are thicker and heavier than standard vinyl planks and are designed to stay in place primarily due to their weight and friction. This method is the easiest to install, but it is also the least stable. While loose-lay planks are less prone to shifting than traditional vinyl sheets, they can still move under heavy traffic or furniture. This method is often used in smaller areas or temporary installations where stability is less critical.

The selection of the appropriate installation method depends on the specific application, the condition of the subfloor, and the desired level of stability. For high-traffic areas or installations where minimal movement is desired, glue-down is generally the preferred method. For DIY projects or where ease of installation is a priority, click-lock offers a viable alternative, provided that proper expansion gaps are maintained.

Subfloor Preparation and its Role in Mitigating Movement

Proper subfloor preparation is paramount to ensuring the long-term stability and performance of vinyl plank flooring, regardless of the installation method. A clean, level, and dry subfloor is essential for preventing unevenness, gapping, and other issues related to movement.

Cleanliness: The subfloor must be thoroughly cleaned to remove dust, debris, and any existing adhesive residue. These contaminants can interfere with the adhesion of glue-down vinyl planks or create unevenness that can cause floating floors to shift or buckle.

Levelness: The subfloor should be as level as possible. Imperfections can cause stress points in the vinyl planks, leading to cracking, gapping, or uneven wear. Self-leveling compounds can be used to correct minor imperfections in concrete subfloors. For wood subfloors, plywood underlayment can be used to create a smooth and level surface. The requirement of levelness is stricter for glue-down installations than click-lock installations.

Dryness: Moisture is a major enemy of all flooring materials, including vinyl. Excess moisture can cause the subfloor to swell or warp, leading to movement and damage to the vinyl planks. A moisture meter should be used to check the moisture content of the subfloor before installation. Concrete subfloors should be properly cured and sealed to prevent moisture migration. Wood subfloors should be inspected for signs of leaks or water damage and repaired as needed. A vapor barrier is typically recommended over concrete subfloors to prevent moisture from permeating through the vinyl.

Failing to properly prepare the subfloor can compromise the installation, even with high-quality vinyl planks and meticulous installation techniques. The time and effort invested in subfloor preparation are essential for ensuring a stable, long-lasting, and visually appealing vinyl plank floor.

In addition to these key points, the quality of the vinyl plank itself plays a crucial role. Thicker planks, especially those with a rigid core, tend to be more dimensionally stable and resistant to movement than thinner, more flexible planks. The wear layer also contributes to the overall durability and resistance to wear and tear, indirectly affecting movement by preventing premature degradation of the material.

Ultimately, the movement of vinyl plank flooring is a complex issue influenced by material properties, environmental conditions, and installation practices. By understanding these factors and taking appropriate precautions, such as proper acclimation, subfloor preparation, and installation techniques, homeowners can minimize the potential for movement and ensure a satisfactory and long-lasting flooring solution.

Installing Vinyl Plank Flooring How To Fixthisbuildthat

A Beginner S Guide To Installing Vinyl Plank Flooring Dumpsters Com

What Is Loose Lay Vinyl Flooring A Plank Guide Reallyfloors America S Est Hardwood

How To Safely Move Furniture Across Vinyl Flooring

20 Tips For A Great Vinyl Plank Flooring Installation

My Vinyl Plank Floor Review Two Years Later Cutesy Crafts

Will Vinyl Plank Flooring Expand And Contract Doityourself Com Community Forums

Install Vinyl Plank From A Hallway Into Room No Transition Strip

Installing Vinyl Plank Flooring How To Fixthisbuildthat

Tips For Installing Vinyl Plank Over Concrete Floors Lemon Thistle

See Also