How to Replace Damaged Floor Joists: A Comprehensive Guide

Floor joists are the horizontal structural members that support the flooring and transfer the load to the foundation walls or beams. Damage to floor joists can compromise the structural integrity of a building, leading to sagging floors, squeaking noises, and potentially dangerous conditions. Identifying and addressing damaged floor joists promptly is crucial for maintaining the safety and stability of a structure. This article provides a detailed guide on how to replace damaged floor joists, ensuring a sound and secure floor system.

Before commencing any repairs, a thorough assessment of the damage is essential. This involves identifying the location and extent of the deterioration, determining the cause of the damage (e.g., moisture, insect infestation, rot), and assessing the condition of adjacent joists and subfloor. A structural engineer or experienced contractor should be consulted if the damage is extensive or if there are concerns about the overall stability of the floor system. Ignoring the underlying cause of the damage when replacing joists will inevitably lead to the same problem recurring over time.

Safety is paramount when working on structural repairs. The work area should be properly supported to prevent collapse during the removal and replacement of joists. Wearing appropriate personal protective equipment (PPE), including safety glasses, gloves, and a dust mask, is essential. Ensure the power is turned off to any electrical circuits running through or near the affected area before commencing work. Stable scaffolding or a secure ladder should be used to access the work area, and proper lifting techniques should be employed to avoid back injuries.

Key Point 1: Preparation and Safety Measures

The success of a floor joist replacement project hinges on thorough preparation and adherence to safety protocols. This phase involves not only assessing the damage but also gathering the necessary tools and materials.

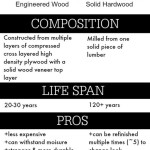

Material Acquisition: The replacement joist should be of the same dimensions and wood species as the original. Using a different size or species can create inconsistencies in the floor system's load-bearing capacity. Pressure-treated lumber is recommended for joists located near the ground or in areas prone to moisture. Ensure the lumber is straight and free from knots or defects.

Tool Collection: The following tools are typically required for floor joist replacement: reciprocating saw, circular saw, drill, impact driver, hammer, pry bar, level, tape measure, safety glasses, gloves, dust mask, shoring posts, temporary support beams, wood chisel, and construction adhesive. Having all the necessary tools readily available will streamline the work process and improve efficiency.

Temporary Support: Before removing the damaged joist, it is crucial to provide temporary support to the adjacent joists and subfloor. This prevents the floor from sagging or collapsing during the repair process. Shoring posts, also known as adjustable steel columns, are commonly used for this purpose. Place the shoring posts directly beneath the joists that border the damaged one, ensuring they are resting on a solid and level surface. A temporary support beam, such as a 4x6 or 6x6 timber, can be placed across the shoring posts to distribute the load more evenly.

Work Area Preparation: Clear the area around the damaged joist of any obstructions, such as furniture, tools, or debris. Remove any flooring or subfloor that is directly above the joist to allow for easy access. This may involve using a pry bar or circular saw to carefully cut and remove the affected flooring sections. Clearly mark the boundaries of the work area to prevent accidental damage to surrounding structures. A chalk line can be used to create straight and precise cutting lines.

By meticulously completing these preparatory steps, the risks associated with the joist replacement process are minimized and ensures for a safer and more efficient workflow.

Key Point 2: Removing the Damaged Joist and Preparing the Area

Following the safety measures and comprehensive preparation, the next step is removing the damaged joist and preparing the area for the new joist. This involves careful cutting and removal techniques to avoid further damage to the surrounding structure.

Cutting the Damaged Joist: Use a reciprocating saw to cut the damaged joist at both ends, where it rests on the sill plate and beam. Make sure to cut beyond the damaged area ensuring the new joist will be resting on solid, undamaged wood. It's crucial to cut the joist cleanly and squarely to ensure a proper fit for the replacement. When cutting, avoid cutting into any plumbing, electrical wiring, or other utilities that may be running through the joist space.

Removing the Joist Sections: Once the joist is cut, use a pry bar or hammer to carefully remove the damaged sections. If the joist is severely deteriorated, it may crumble easily. Work slowly and methodically to avoid causing further damage to the adjacent joists or subfloor. If the joist is nailed or screwed to the subfloor, use a pry bar or nail puller to remove the fasteners. Take breaks as needed, as removing a large joist can be physically demanding.

Cleaning the Area: After removing the damaged joist, thoroughly clean the area. Remove any debris, such as loose wood, nails, or insulation. Use a wire brush or scraper to remove any remaining rot or fungus from the adjacent joists and sill plate. Vacuum the area to remove dust and debris. A clean work area will ensure a better bond between the new joist and the existing structure.

Inspecting Adjacent Structures: Once the damaged joist is removed, examine the adjacent joists, sill plate, and subfloor for any signs of damage. If any additional damage is found, address it before installing the new joist. Repair or replace any damaged components to ensure the structural integrity of the floor system. Applying a wood preservative to the exposed wood surfaces can help prevent future rot and insect infestation.

Measuring for the New Joist: Accurately measure the distance between the sill plate and the beam to determine the length of the new joist. Double-check the measurement to ensure accuracy. The new joist should fit snugly but not too tightly between the supports. A slightly loose fit is preferable to a fit that is too tight, as it will allow for expansion and contraction of the wood. Subtract ¼” from the measurement to ensure proper installation.

By adhering to these meticulous procedures, the process of removing the damaged joist is executed with precision. This, in turn, sets the stage for a successful joist replacement project.

Key Point 3: Installing the New Joist and Securing It in Place

With the damaged joist removed and the area prepared, the final step involves installing the new joist and securing it in place. This requires careful alignment and secure fastening to ensure the new joist integrates seamlessly with the existing structure.

Fitting the New Joist: Carefully slide the new joist into place, ensuring it rests squarely on the sill plate and beam. Use a hammer and wood block to gently tap the joist into position. Avoid using excessive force, as this could damage the joist or the surrounding structure. Ensure there is an even gap between the joist and the adjacent joists.

Securing the Joist to the Sill Plate and Beam: Fasten the new joist to the sill plate and beam using appropriate fasteners, such as galvanized nails or structural screws. The type and spacing of the fasteners will depend on the size of the joist and the local building codes. Typically, fasteners should be spaced 12 to 16 inches apart. Use an impact driver to install the screws securely and prevent them from stripping. Toenailing, driving nails at an angle through the joist into the sill plate or beam, can provide additional strength.

Adding Bridging or Blocking: Bridging or blocking is used to provide lateral support to the floor joists and prevent them from twisting or buckling. Install bridging or blocking between the new joist and the adjacent joists. Solid blocking is typically used for short spans, while cross bridging is used for longer spans. Ensure the bridging or blocking is securely fastened to the joists using nails or screws. The addition of bridging or blocking significantly increases the stability and load-bearing capacity of the floor system.

Applying Construction Adhesive: For increased strength and to reduce squeaking, apply construction adhesive to the top of the joist before reinstalling the subfloor. This will create a stronger bond between the joist and the subfloor, minimizing movement and noise. Use a high-quality construction adhesive that is specifically designed for wood-to-wood bonding. Follow the manufacturer's instructions for application and curing time.

Reinstalling the Subfloor and Flooring: Once the new joist is securely in place and the adhesive has cured, reinstall the subfloor and flooring. Use the same type of fasteners that were originally used to install the subfloor and flooring. Ensure the subfloor is properly aligned with the joists and is securely fastened. If necessary, replace any damaged or deteriorated subfloor sections. Once the subfloor is reinstalled, install the flooring according to the manufacturer's instructions. Ensure there are no gaps or loose boards. Stagger the seams of the flooring to prevent weak points.

By diligently following these instructions, the new joist is not only properly installed but also fully integrated into the existing floor system, ensuring long-term stability and performance.

Replacing damaged floor joists is a complex task that requires careful planning, execution, and adherence to safety protocols. By following the steps outlined in this guide, homeowners and contractors can effectively address damaged floor joists and restore the structural integrity of the floor system. Remember to consult with a structural engineer or experienced contractor if the damage is extensive or if there are any concerns about the overall stability of the structure. Proper maintenance and regular inspections can help prevent future damage and ensure the longevity of the floor system.

Fix Replace Damaged Floor Joists How To Sister A Joist

How To Repair A Butchered Floor Joist Fine Homebuilding

How To Replace A Floor Joist

Everything You Need To Know About Floor Joist Repair

Replace Damaged Board Floor Sheathing Fine Homebuilding

Everything You Need To Know About Floor Joist Repair

Rotten Floor Joist Replacement On A Massive Scale Entire House Project

Floor Joists Common Problems And Joist Repairs

Repairing Floor Joists What Homeowners Need To Know

Floor Joists Common Problems And Joist Repairs

See Also