Simulated Wood Flooring: Essential Aspects for Informed Decisions

Simulated wood flooring has emerged as a sought-after alternative to traditional hardwood, offering a multitude of benefits and cost-effective advantages. Understanding these essential aspects will help you make an informed decision when selecting this durable and versatile flooring option.

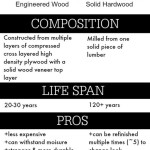

Composition and Construction

Simulated wood flooring is typically manufactured from composite materials, such as high-density fiberboard (HDF) or vinyl. HDF is made from recycled wood fibers and resins, providing a stable and dense base. Vinyl planks, on the other hand, consist of multiple layers, including a rigid core and a top layer that mimics the appearance of wood grain.

Wood Grain Authenticity

Advances in printing technology have enabled simulated wood flooring to replicate the natural look and texture of real wood incredibly accurately. The top layer of the planks features high-resolution photographic images of various wood species, from warm oak to rustic pine. Some products even incorporate textured embossing to enhance the realistic feel.

Durability and Scratch Resistance

Simulated wood flooring is engineered to withstand heavy foot traffic and daily wear and tear. The durable construction and surface coatings provide exceptional scratch resistance, making it ideal for both residential and commercial applications. This longevity ensures that your flooring investment will last for years to come.

Water Resistance and Stain Resistance

Unlike traditional hardwood, simulated wood flooring is highly water-resistant. Vinyl planks feature a waterproof core, while HDF planks are treated with moisture-resistant sealants. This resistance makes it suitable for areas prone to spills or moisture, such as kitchens, bathrooms, and mudrooms. Additionally, the surface finish is stain-resistant, preventing the absorption of liquids like coffee or wine.

Installation and Maintenance

Simulated wood flooring offers a convenient installation process. HDF planks are typically installed using a floating method, eliminating the need for glue or nails. Vinyl planks often feature a click-lock system, allowing for a quick and easy do-it-yourself installation. Maintenance is equally effortless, with regular sweeping or mopping sufficient to keep your floors looking pristine.

Environmental Benefits

Choosing simulated wood flooring contributes to environmental sustainability in several ways. It reduces the demand for trees used in traditional hardwood production, promoting forest conservation. Additionally, HDF planks are made from recycled materials, reducing the environmental impact of waste. The use of durable and long-lasting flooring also minimizes the need for frequent replacements, saving resources and landfill space.

Cost Considerations

Compared to its hardwood counterpart, simulated wood flooring is significantly more cost-effective. The production process of composite materials is less expensive than milling and finishing real wood. This cost savings is passed on to consumers, making it an attractive option for those on a budget. The long lifespan and low maintenance requirements further contribute to its cost-effectiveness in the long run.

The Best Fake Wood Flooring 4 Faux Floor Ideas Inc

8 Fake Wood Flooring Options 2024 A Full Guide And Reviews

The Best Fake Wood Flooring 4 Faux Floor Ideas Inc

Engineered Flooring Vs Laminate Everything You Need To Know Forbes Home

Is Engineered Hardwood Real Or Fake Wood

Laminate Flooring The Home

Engineered Hardwood Vs Laminate Flooring What S The Difference

Our Flooring Solid Wood Vs Faux Tile Chris Loves Julia

Knowledge What Is Laminate Wood Flooring Interio Floors

Mode 8 In X 48 Color Summer Laminate Wood Flooring 21 26 Sq Ft Carton Com

See Also