What Is The Most Scratch Resistant Flooring?

Selecting the appropriate flooring for a home or commercial space necessitates careful consideration of various factors, with scratch resistance being paramount for maintaining aesthetic appeal and minimizing long-term maintenance costs. Scratches detract from the visual quality of flooring, particularly in high-traffic areas or households with pets. Understanding the properties that contribute to scratch resistance is crucial for making an informed decision. This article will delve into the characteristics of different flooring types, evaluating their performance against scratching and highlighting those that offer superior durability.

The propensity of a flooring material to scratch is influenced by its hardness, density, and surface treatment. Hardness, often measured using the Janka hardness scale for wood flooring, indicates the resistance of a material to indentation. Denser materials generally offer greater resistance to scratching because they can withstand more pressure before the surface is compromised. Surface treatments, such as protective coatings and sealants, can also significantly enhance a flooring's ability to resist scratching by providing an additional layer of protection.

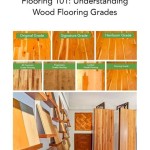

Hardwood Flooring and Scratch Resistance

Hardwood flooring, prized for its natural beauty and longevity, presents a spectrum of scratch resistance depending on the species and finish. The Janka hardness scale provides a numerical representation of a wood's resistance to denting and scratching. Species such as Brazilian Walnut (Ipe) and Hickory rank high on the Janka scale, indicating superior hardness and scratch resistance compared to softer woods like Pine or Cherry. It is important to note that even the hardest wood is not completely immune to scratching; sharp objects or abrasive materials can still damage the surface.

The finish applied to hardwood flooring plays a significant role in its scratch resistance. Polyurethane finishes, particularly those with multiple coats and aluminum oxide additives, offer a durable protective layer that can withstand everyday wear and tear. Pre-finished hardwood flooring often features more robust factory-applied finishes compared to site-finished flooring, enhancing its scratch resistance right from installation. Regularly maintaining the finish is critical to preserving its protective properties and preventing scratches from penetrating the wood itself.

Despite the inherent beauty and durability of hardwood, it is susceptible to scratches from pet claws, furniture movement, and tracked-in dirt and debris. Implementing preventative measures, such as using area rugs in high-traffic areas, placing felt pads under furniture legs, and regularly sweeping or vacuuming to remove abrasive particles, can significantly reduce the likelihood of scratches and extend the lifespan of hardwood flooring.

Laminate Flooring and Scratch Resistance

Laminate flooring is engineered to mimic the appearance of natural materials, such as wood or stone, while offering enhanced durability and affordability. Its construction typically consists of a wear layer, a decorative layer, a core board, and a backing layer. The wear layer, often made of aluminum oxide, is the primary determinant of scratch resistance. Thicker and more durable wear layers provide greater protection against scratches and abrasions.

The Abrasion Class (AC) rating system is used to assess the wear resistance of laminate flooring. AC ratings range from AC1 to AC5, with higher numbers indicating greater durability and scratch resistance. Flooring with an AC3 rating is suitable for general residential use, while AC4 and AC5 ratings are recommended for high-traffic areas or commercial applications. Selecting laminate flooring with an appropriate AC rating is essential for ensuring long-term performance in the intended environment.

While laminate flooring offers good scratch resistance, it is not impervious to damage. Sharp objects or excessive force can still scratch the surface. Unlike hardwood flooring, laminate cannot be sanded and refinished to remove scratches. Therefore, preventative measures, such as those recommended for hardwood flooring, are equally important for maintaining the appearance of laminate flooring. Additionally, choosing a laminate flooring product with a textured surface can help to camouflage minor scratches and imperfections.

Vinyl Flooring and Scratch Resistance

Vinyl flooring, available in sheet, tile, and plank formats, is known for its water resistance, affordability, and ease of maintenance. Its scratch resistance varies depending on the type of vinyl flooring and the thickness of the wear layer. Luxury vinyl tile (LVT) and luxury vinyl plank (LVP) flooring generally offer superior scratch resistance compared to standard vinyl sheet flooring due to their thicker construction and more durable wear layers.

The wear layer of vinyl flooring is measured in mils (thousandths of an inch). Thicker wear layers provide greater protection against scratches, scuffs, and stains. For residential applications, a wear layer of 12 mils or greater is recommended for high-traffic areas or households with pets. Commercial applications may require even thicker wear layers, such as 20 mils or greater, to withstand heavy foot traffic and potential abrasions.

Some vinyl flooring products feature enhanced surface treatments, such as urethane coatings with ceramic bead additives, to further improve scratch resistance. These coatings provide an additional layer of protection against everyday wear and tear. While vinyl flooring is generally more scratch-resistant than standard linoleum, it is still susceptible to damage from sharp objects or abrasive materials. Regular cleaning and maintenance, along with preventative measures like using floor protectors under furniture, are essential for preserving the appearance of vinyl flooring.

Tile Flooring and Scratch Resistance

Tile flooring, including ceramic and porcelain tile, is renowned for its exceptional durability and scratch resistance. Porcelain tile, in particular, is known for its high density and hardness, making it highly resistant to scratching, chipping, and staining. Ceramic tile, while still a durable option, is generally less dense and scratch-resistant than porcelain tile.

The Porcelain Enamel Institute (PEI) rating system is used to assess the abrasion resistance of tile flooring. PEI ratings range from 1 to 5, with higher numbers indicating greater resistance to abrasion and scratching. Tile with a PEI rating of 3 is suitable for light to moderate foot traffic, while tile with a PEI rating of 4 or 5 is recommended for high-traffic areas or commercial applications.

While tile flooring is exceptionally scratch-resistant, it is not completely impervious to damage. Abrasive materials, such as sand or grit, can potentially scratch the surface of the tile over time. Additionally, grout lines between tiles are susceptible to staining and discoloration. Regular cleaning and maintenance, including sweeping or vacuuming to remove abrasive particles and sealing the grout lines to prevent staining, can help to preserve the appearance of tile flooring.

Engineered Wood Flooring and Scratch Resistance

Engineered wood flooring offers a balance of aesthetics and practicality. Constructed with a thin veneer of hardwood adhered to a core of plywood or high-density fiberboard (HDF), it provides dimensional stability and can be installed in areas where solid hardwood is not suitable. Its scratch resistance is primarily determined by the hardness of the veneer and the quality of the finish applied.

As with solid hardwood, the species of wood used for the veneer significantly impacts scratch resistance. Harder wood species, such as oak, maple, or hickory, will naturally be more resistant to scratches than softer species like pine or fir. The thickness of the veneer also plays a role; thicker veneers generally offer more resilience to surface damage.

The finish applied to engineered wood flooring is equally important. Durable polyurethane finishes, especially those enhanced with aluminum oxide or ceramic particles, provide a robust protective layer against scratches and scuffs. Pre-finished engineered wood flooring often boasts factory-applied finishes that are highly resistant to wear and tear. Maintaining the finish with regular cleaning and the use of appropriate cleaning products is crucial for preserving its protective qualities and preventing scratches.

Engineered wood, like solid hardwood, can be susceptible to scratching from pets, furniture, and tracked-in debris. Employing preventative measures such as area rugs, felt pads under furniture, and regular sweeping or vacuuming can significantly reduce the risk of scratches and prolong the life of the floor.

Other Flooring Options and Scratch Resistance

Beyond the common flooring types discussed, other options exist, each with varying degrees of scratch resistance. Concrete flooring, when properly sealed and finished, can offer exceptional durability and resistance to scratching. Epoxy coatings applied to concrete floors further enhance their scratch resistance and create a seamless, easy-to-clean surface.

Cork flooring, while known for its comfort and eco-friendliness, is relatively soft and prone to scratching. However, modern cork flooring often features durable finishes that improve its scratch resistance. Regular maintenance and the use of protective mats in high-traffic areas can help to minimize scratching.

Bamboo flooring is another sustainable option that offers moderate scratch resistance. Strand-woven bamboo, in particular, is known for its hardness and durability. However, all bamboo flooring is susceptible to scratching from sharp objects and abrasive materials. Maintaining the finish and using preventative measures are essential for preserving its appearance.

Ultimately, the "most" scratch-resistant flooring option depends on the specific needs and priorities of the user. Tile, especially porcelain, offers the highest level of scratch resistance but may not be suitable for all environments due to its hardness and coldness. Laminate flooring provides a good balance of scratch resistance and affordability, while vinyl flooring offers water resistance and ease of maintenance. Hardwood and engineered wood offer natural beauty but require more care to prevent scratching. Understanding the properties of each flooring type and implementing preventative measures are crucial for selecting the best option for long-term performance and aesthetic appeal.

Best Engineered Hardwood Floor For Scratch Resistance Lifecore Flooring S

Best Waterproof My Dad S Flooring America

Best Waterproof My Dad S Flooring America

Hardwood Flooring That Will Not Scratch Garrison Collection

Scratch Resistant Flooring Which Material Is The Best Lamont Bros

Hardwood Flooring That Will Not Scratch Garrison Collection

Scratch Resistant Laminate Flooring At Com

What Is The Most Scratch Resistant Engineered Wood Flooring

Are There Any Scratch Resistant Hardwood Flooring Options Woodfloor Masters Inc

4 Most Scratch Resistant Floors That Don T Cost A Fortune

See Also